Call us at 718-215-0285

Your Trusted Partner for U.S. Based

CNC Fabrication Services

Call us at 651-661-5192

CNC Fabrication

Services

Specializing in CNC cutting, welding, and machining, we partner with our customers to provide turnkey fabrication services.

Our 40,000 sf facility in Minnesota filled with highly automated machinery enables us to efficiently fabricate a broad range of parts and weldments with high-quality and short lead times.

Turnkey Capabilities

Low MOQ / High Complexity

High Production Capacity

State-Of-The-Art Equipment & Processes

Fill out the form and we'll be in touch in 2 hours or less!

METAL FABRICATION

Elevated Steel is your go-to company for metal fabrication. We are a custom fabricator and designer that offers a comprehensive range of services.

Design assistance

Fabrication (steel, aluminum, stainless, and more)

Welding

Finishing (powder coating, galvanization, wet coating)

Assembly

nstallation anywhere in the U.S.

We use only the best materials available to create strong, long-lasting products and work closely with our clients to provide specialized solutions that meet their demands. Keeping up with the latest technology and best practices are just some of the ways we’re striving to be your resource for all aspects of metal fabrication.

Fabrication Capabilities

With our 40,000 sf fabrication shop located in Minnesota and a team of highly skilled operators, machinists and welders, Laser 1 is proud to be a nationwide partner for contract manufacturing. From laser cutting and machining to welding and coating, there's almost no job that we can't handle. When you need a partner, we have the capacity and the expertise to get you a quality product at a competitive price delivered on time.

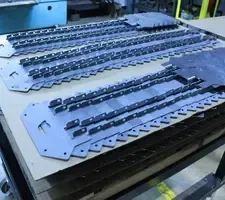

Laser Cutting

Mitsubishi EX-F 8000W Fiber Laser

3015 Smart Flex RAPID 8 Shelf Tower

Our Fiber Laser delivers ultra-fast, high-precision cutting of both thick and thin metals, while the RAPID 8-Shelf Tower provides automated material handling. Together, they provide high capacity, accuracy, and efficiency for our customers.

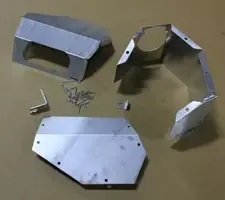

Bending & Forming

CNC Press Brakes (Up to 110 Tons)

With up to 110 ton capacity, our CNC press brakes provide precise, repeatable bending and forming of sheet metal, ensuring tight tolerances and consistent quality across both simple and complex parts.

Milling & Turning

HAAS CNC Mill

HAAS CNC Turning Center

Our HAAS CNC equipment delivers precision milling and turning capabilities, enabling the production of complex geometries and precision components across a wide range of materials and volumes.

Tube Cutting

Hans Tube Laser

Our Hans Tube Laser offers advanced multi-axis tube cutting, capable of processing round, square, rectangular, and specialty profiles with precision and efficiency, reducing secondary operations and ensuring quality in every part.

Our Areas Of Expertise

With modern equipment and experienced fabricators and machinists, we've got the capacity and know-how to get you what you need for almost every application.

Industrial Tubing

Weldments

Housings

Railing & Fencing

Sheet Metal

Flat Parts

Custom Brackets

Motor Laminations

OEM Parts

Couplings

Rods & Shafts

Specialty Parts

Turnkey Manufacturing Capabilities

In addition to our fabrication and machining services, we also offer upstream and downstream services that allow us to be a turnkey solution for our customers! From welding and grinding custom frames to product assembly and powder coating, we've got you covered with end-to-end solutions!

Welding

TIG Welding

MIG Welding

Stud & Nut Welding

Spot Welding

Packaging & Assembly

Sub-Assembly

Packaging

Stocking

Order Fulfillment

Design

Concept Creation

Prototype Design

Fabrication Drawings

DFM Consulting

Finishing & Coating

Blasting & Powder Coating

Plating

Heat Treatment

Laser Marking

Materials

Our modern, flexible equipment allows us to efficiently process a wide variety of materials, including stainless, aluminum, HDPE and exotic alloys.

METALS

PLASTICS & COMPOSITES

Carbon Steel

Stainless Steel

Aluminum

Brass

Tool Steel

Inconel 615 & 718

Brass Alloys

All Other Non-Toxic Metals

PLASTICS & COMPOSITES

Acrylic

HDPE

UHMW

Nylon

About Us

ELEVATED STEEL

We are a TURNKEY solution! For decades, we’ve built our business on consistently going above and above for our customers. We pride ourselves on the fabrication that is both high-quality and on time.

We strive to stand out from the rest of the fabrication and installation companies. We want to collaborate with our clients in every project we take on and to work with partners who are reliable and trustworthy.

OUR CUSTOMERS

Why Work With Us

With 40,000 sf of shop space filled with modern equipment and a top notch team of fabricators, Laser 1 combines high volume production with expert craftsmanship. From our Minnesota facility, we cut, weld, machine, coat, assemble, and package with pride because we know that our customers' success is our success.

ADVANCED

CAPABILITIES

Our highly automated equipment and ISO-compliant processes enable us to deliver our customers' orders with shorter lead times and higher quality. Our Staff are dedicated to making our customers successful, one order at a time!

SUPERIOR

QUALITY

Quality is built in, such that getting it right the first time is the expectation. From our initial meeting to quoting to order delivery, our advanced product quality planning process is engineered to provide our customers with a reliable supply chain.

EFFICIENT COMMUNICATION

We provide customers with a single point of contact for all their manufacturing needs, simplifying the complexity of dealing with multiple vendors and enhancing collaboration to improve efficiency.

How We Ensure Quality

At Laser 1, quality is a commitment built into every stage of production. With a leadership team that has over a century of combined expertise in contract manufacturing and a full suite of inspection tools, including CMM (Coordinate Measuring Machine), Optical Comparator, and InspecVision systems, Laser 1 guarantees precision and dimensional accuracy in every part.

The CMM enables tactile, high-accuracy measurement of complex geometries, while the Optical Comparator offers visual verification against design specifications. Our InspecVision technology adds another layer of confidence with rapid, non-contact optical inspection ideal for sheet components and high-throughput environments .

Let’s talk about your project

Industries Served

With extensive experience across a number of industries, we partner with customers wherever efficiency and supply chain stability is required.

INDUSTRIAL

AEROSPACE

AUTOMOTIVE

MEDICAL

MANUFACTURING

MILITARY

Frequently Asked Questions

What Size Sheets Can You Cut?

Our laser cutting machine and automated feeding system can handle sheets up to 60" x 120".

What Is Your Typical Lead Time?

Our goal is to get estimates send out within 24-48 hours, but sometimes difficult to source materials take more time. We will quote the current lead time with the estimate. This is generally 2-3 weeks, depending on the size of your job and our current work load. We offer expedite services for an additional fee.

What Is Your Accuracy?

It depends on the material and the equipment we use, but we can hold tolerances as low as 0.002" for most applications.

How Thick Can You Cut?

Our laser table can cut material from 0.003" to 1.0" thick. See below for details.

Mild Steel .003”- 1”

Stainless Steel .003”- 0.5”

Aluminum .040”- 0.5”

Galvanized .020”- 0.5”

Brass .040”- 0.50”

Copper .040”- .250

What Types of Files Do You Work With?

Solid part files (.sldprt) are preferred. We can also use most other CAD file types.

If you don't have a file, our design team can reverse engineer your part.

ABOUT LASER 1 TECHNOLOGIES

Your Local Partner For CNC Fabrication

Since 1998, Laser 1 has been providing US-based contract fabrication solutions for customer across diverse industries and applications. With highly automated equipment and quality processes, our efficiency allows us to be competitive for customers looking to onshore manufacturing.

Our leadership team has over 100 years of combined expertise in laser cutting and precision fabrication, which enables us to tackle complex, multifaced projects and provide a simple, consolidated solution for our customers.

Every part we produce is backed by our rigorous quality control processes. Our commitment to quality, responsiveness, and on-time delivery continue to earn the trust of customers looking for local manufacturing solutions.

In an era defined by volatility and uncertainty, our extensive capabilities and streamlined operations ensure our customers receive consistent quality and reliable delivery, so they can focus on what they do best.

Let’s talk about your project

When you choose Laser 1, you're not just choosing a supplier; you're choosing a partner dedicated to your success.

Connect With Our Team!

We respond quickly, so message us or give us a call so that we can get you the supply chain solution you've been looking for.

Office Hours:

Monday - Friday

8:00 am to 5:00 pm

Phone:

Manufacturing Facility:

1689 Oakdale Avenue, Suite 102

West St. Paul, MN 55118

Let’s talk about your project

LASER 1 TECHNOLOGIES

We're your local partner for CNC fabrication!

Reach out for an accurate quote and reliable delivery!

Laser Cutting

Machining

Welding

Assembly

Packaging

EQUIPMENT WE USE

Voortman V807

Plasma Cutter

EMI EL2

20’ brake

20’ shear

WE FOCUS ON QUALITY

AISC Compliant

Every part is quality checked

Certified Welders – 1,2,3,4G certifications (MIG and stick welding), GMAW and SMAW

AWS D1.1 compliant

LET'S TALK ABOUT YOUR PROJECT

For decades, we’ve built our business on consistently going above and above for our customers. We pride ourselves on fabrication that is both high quality and on time. We collaborate with our clients on every project we take on and to work with partners who are reliable and trustworthy.

Reach out to us by calling us or filling out this form and we will be in touch to talk about your project as soon as we can.

CONTACT INFORMATION